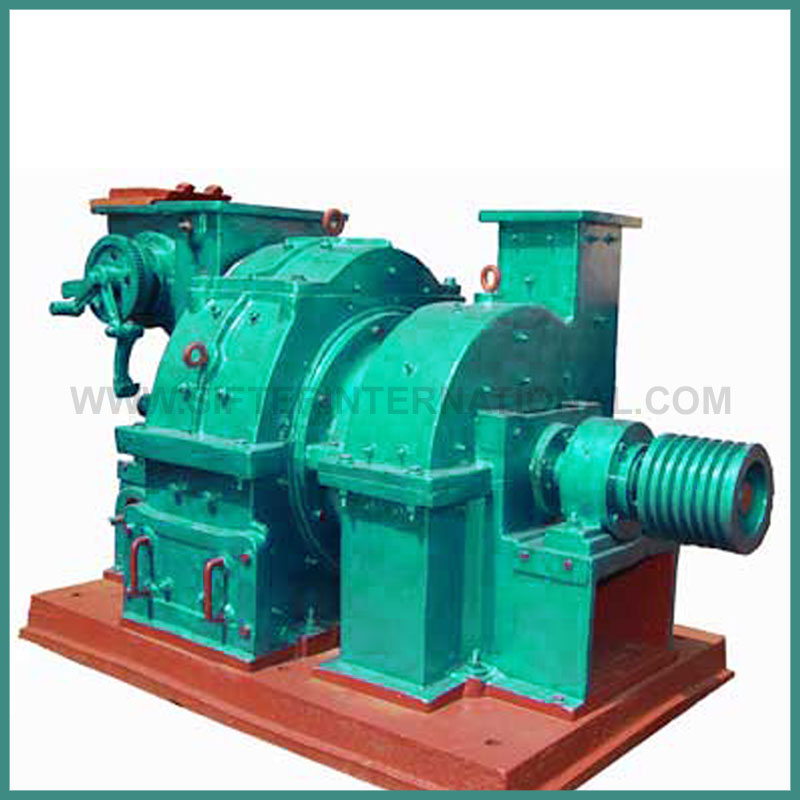

Flaking roller mill machine is used for oilseed crushing, extraction of vegetable oil, and widespread use of cereal flacking like chiwra, dal, and corn flakes. Industrial Flaking Roller Mill Machine is simple and with robust construction and easy in operation and maintenance.

Advance Roller Mill Machine

Sifter International developed and supplied a new generation flacking roller mill for the soya industry with the following new feature. We have supplied these flakes to the USA & other countries.

Technical specification

1. Sturdy mild steel body.

2. Roll adjustment by hydraulic power pack with the provision of auto /manual.

3. Hydraulic cylinder piston and sleeve imported from Italy and all oil seals are German make. Least chances for leakages and damage. Arms are forged material.

4. Strong rare earth magnetic plate is provided on the entire length of the roll to avoid ferrous particles between the two rolls.

5. In case any nonferrous nut, bolt, or washer falls between two rolls it will pass between two rolls without damaging the roll. For this solution, we are providing a nitrogen gas-filled accumulator (shock absorber) in our hydraulic power pack for extra security.

6. Scrapper required to clean the surface of both rolls we have provided high-class steel alloys scrapper. These scrapper does not spoil the rolls. These scrappers automatically adjust the pressure on rolls by pneumatic control valves. No need for daily adjustment.

7. We have provided a temperature indicator circuit on each bearing of flaker and show it digitally on the panel board.

8. Split type bearing body for easy removing of rolls from flaker body.

9. On-line surface grinding attachment attached to the body. You can finish the surface without removing the roll from the body.

10. We provided a low-level sensor in the hopper of the flacking roller mill. It will indicate the bell if the material reaches a low level. In that case either you put the material in the hopper or it will create a gap between two rolls within 30 seconds. At the same time, scrappers will also move away from the rolls. When the material reaches at feed roll the rolling mill automatically goes to close the position with the prescribed pressure and at the same time scrapper will come in on position.

11. The complete panel is PLC controlled and digital visible in your control room and your mobile also.

12. The capacity of flaker digitally shown and managed by a rotary feeder with a variable drive.

13. More features can be added on request.

14. Hydraulic system for replacement of bearing along with bearing body.

15. Touch screen display system on panel board

All contact parts are made up of SS-304. The capacity range is available from 400 kg to 1000 kg/hr. For more detail and specification you can send your valuable inquiry to us. We will revert back to you immediately. With the matching capacity seed cracker and seed, the cleaner is also available with us.